Walmart inventory management can be like a balancing act. Too little stock means missed sales, while too much leads to high storage costs. Walmart provides powerful tools to help sellers manage their inventory efficiently, but knowing how to use them effectively is the key.

In this guide, we’ll break down Walmart’s inventory management system, best practices for avoiding stock issues, and strategies to improve inventory turnover. Whether you use Walmart Fulfillment Services (WFS) or handle shipping yourself, these insights will help you keep your products available, minimize losses, and boost your business. Let’s dive in!

What is Inventory Management and its Importance?

Inventory management refers to tracking and handling the inflow and outflow of items in the warehouse so that you are always in stock and ready to fulfill customer demand. Managing your inventory effectively helps avoid overstocking and getting stuck with stranded or expired items.

Effective inventory management is crucial to the success of your online business, as it ensures that you never miss out on potential sales and that your listings are always active and available for shipment. This is not only necessary for sales and revenue but also vital for customer trust.

Being out of stock can result in a high order cancellation rate that damages your account health and can lead to suspension.

How Does Walmart Inventory Management System Work?

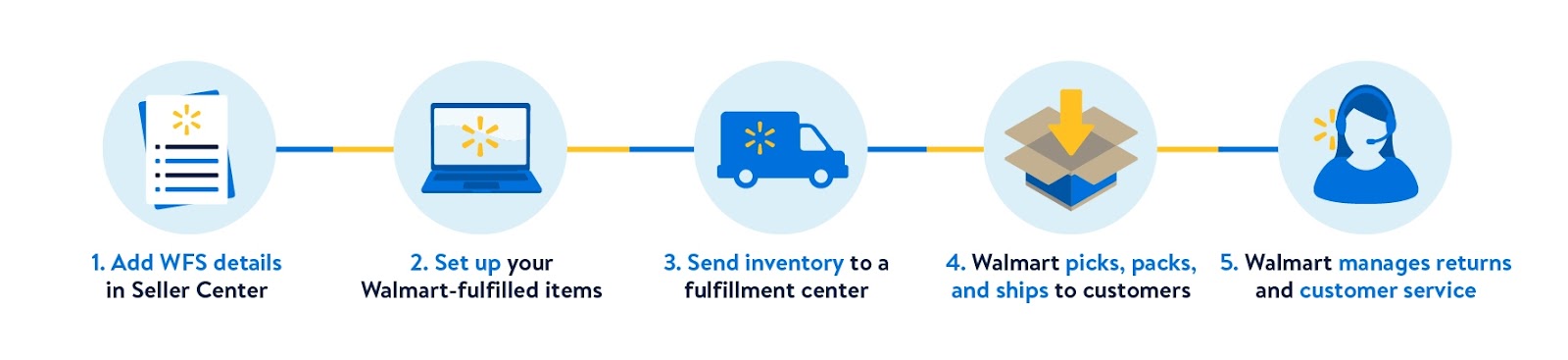

Walmart provides WFS sellers with an efficient inventory management system where they can send their items to the fulfillment centers, and Walmart manages the packing, shipping, and customer service. Walmart WFS sellers can manage their inventory in Seller Center by monitoring the items in stock, historical sales data, and daily units sold. They also receive suggestions from Walmart about restocking based on the current inventory and forecasted sales.

Also Read: 7 Walmart Account Management & Selling Strategies that Boost Sales

How to Manage Walmart Inventory in Seller Center?

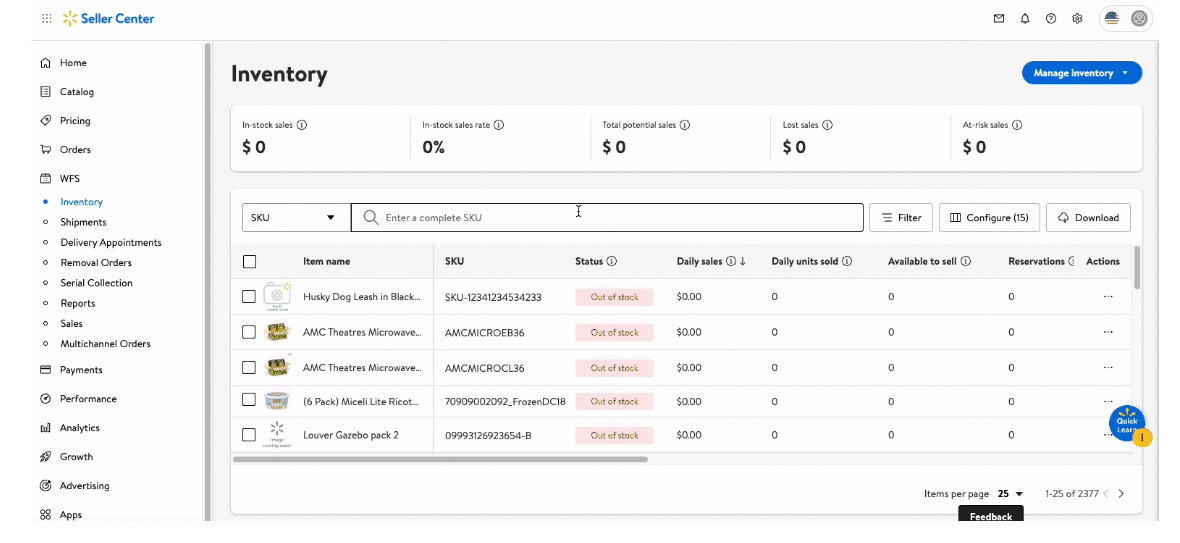

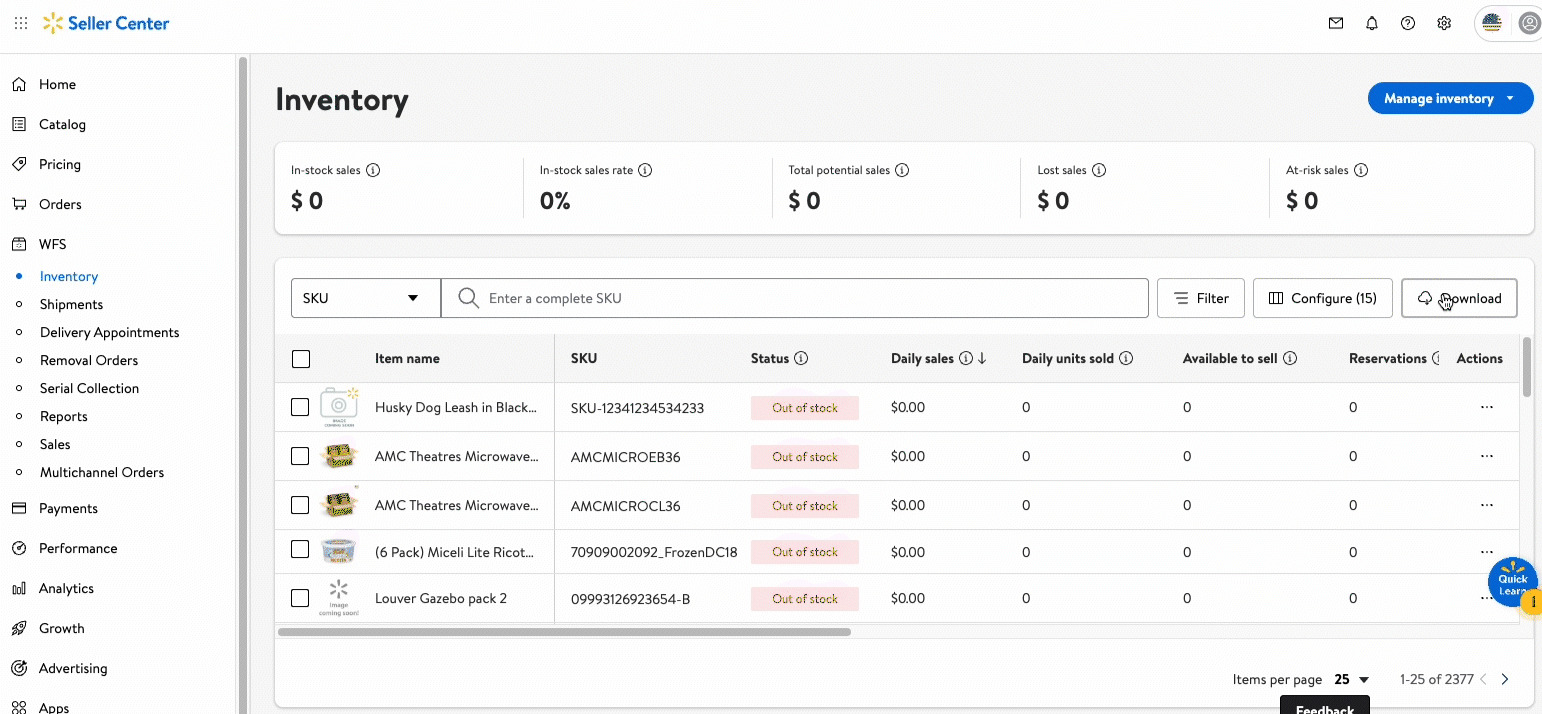

You can manage your Walmart inventory by logging into Seller Center and navigating to the Inventory page. It shows you the predicted daily sales you may lose due to being out of stock and the daily sales you’ll lose if you don’t restock. Monitoring this data helps you maximize your sales and avoid stockouts.

On the Inventory page, you can track the status of your inventory items, including daily units sold, available units, and reservations.

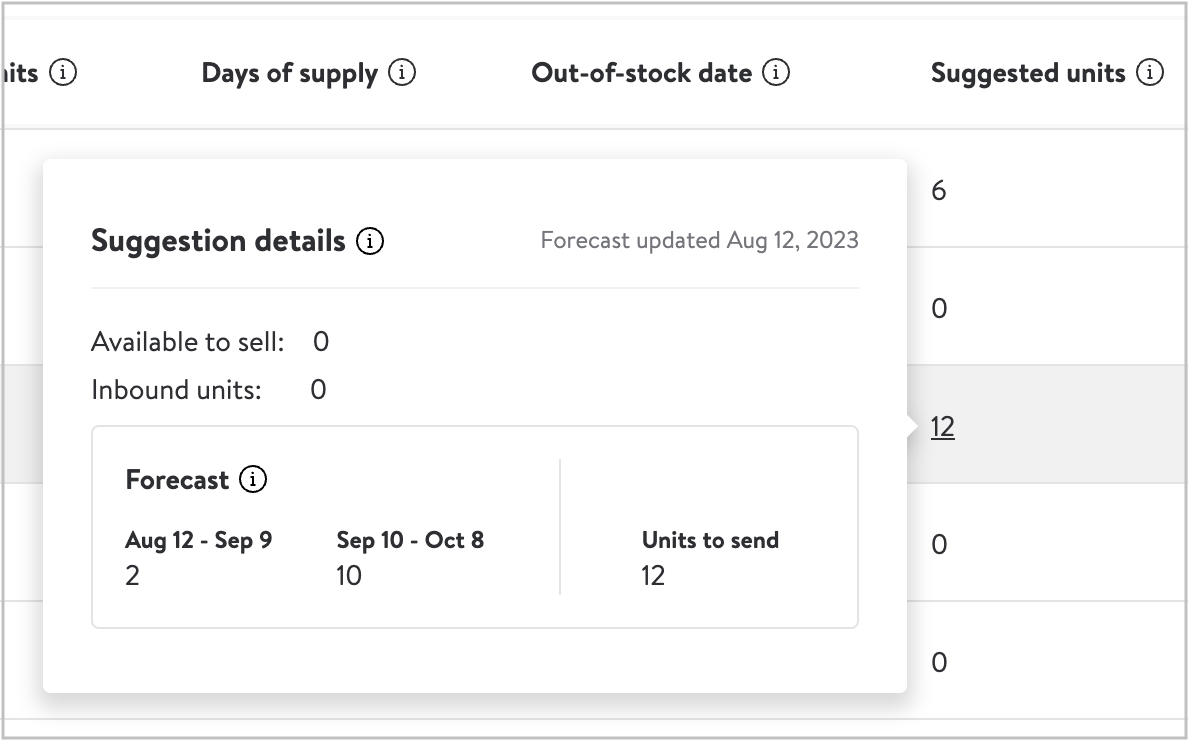

Walmart offers recommendations about replenishing your WFS inventory and how many units to send to the fulfillment center. The recommendations are based on your currently available inventory, inbound inventory, and sales forecast for the next 8 weeks.

You can also find your past 30 days’ sales and performance data on the Inventory page, which helps you make better inventory decisions.

Walmart prioritizes your WFS inventory for order fulfillment and only switches to non-WFS inventory once the WFS inventory is sold out.

2 Ways to Restock Your Walmart Inventory

Log into Seller Center and go to Inventory.

- Option 1: Click on the Manage Inventory button and select Send Inventory from the dropdown menu. This will guide you through the Create Inbound Order process, where you can search for and choose the items you want to send.

- Option 2: Select items directly from the table, then choose Send Inventory from the available options to add them to a new inbound order.

Also Read: Understanding Walmart Seller Fees: A Complete Guide for New Sellers

How to Monitor Your WFS In-Stock Inventory

Once you’ve sent items to a Walmart fulfillment center, they become part of a shared inventory pool. Walmart doesn’t allocate specific units to each sales channel; instead, orders are fulfilled on a first-come, first-served basis.

Typically, inventory stored at fulfillment centers can be used for Walmart orders, off-Walmart orders, or both. However, some units may be housed in specialized facilities that support multichannel fulfillment, meaning only a portion of your total inventory may be available for off-Walmart orders.

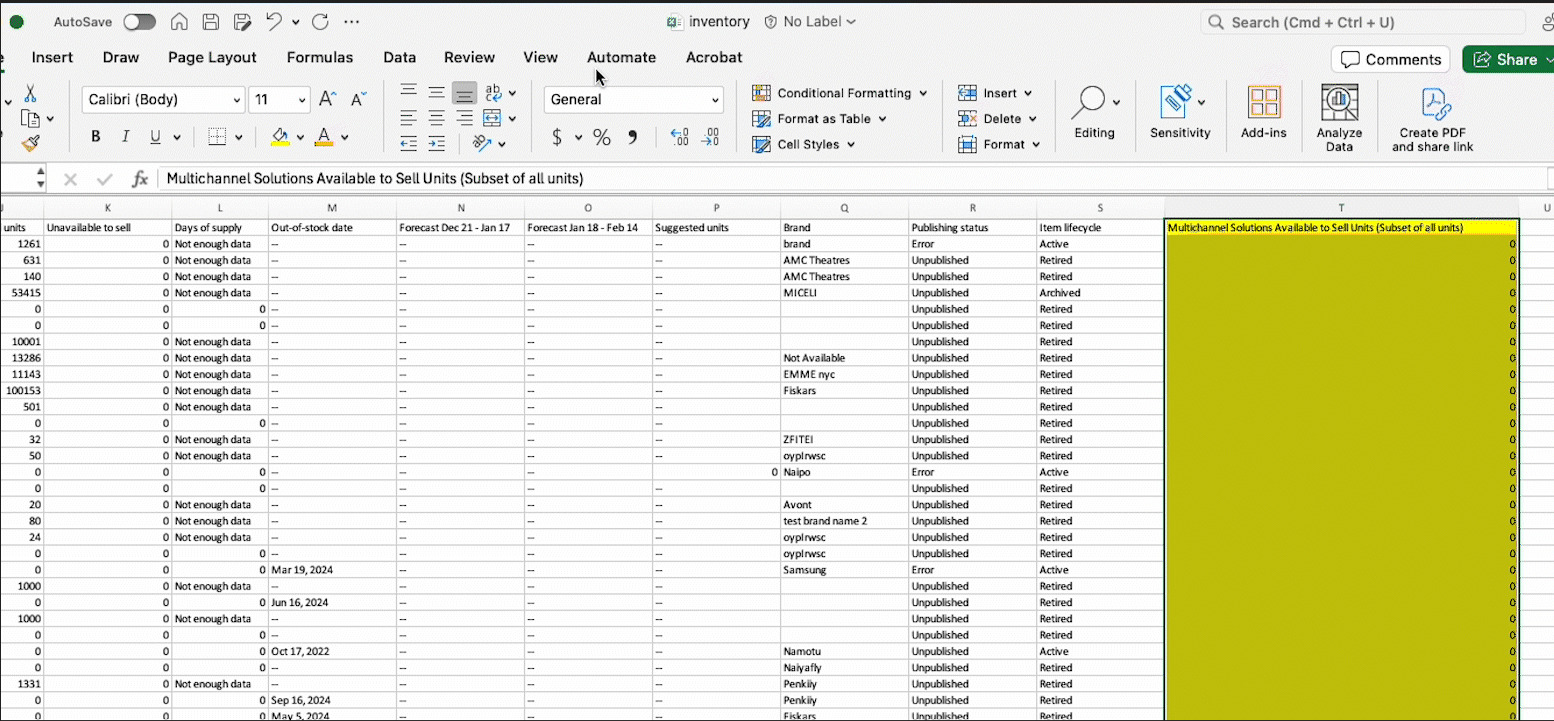

Here’s how you can check your real-time stock levels for both Walmart and off-Walmart orders:

1. Log into Seller Center and navigate to Inventory.

2. Download the inventory list by clicking Download at the top right of the table.

3. In the downloaded file, you can see the number of units and their status at that moment.

Walmart Inventory Health Report

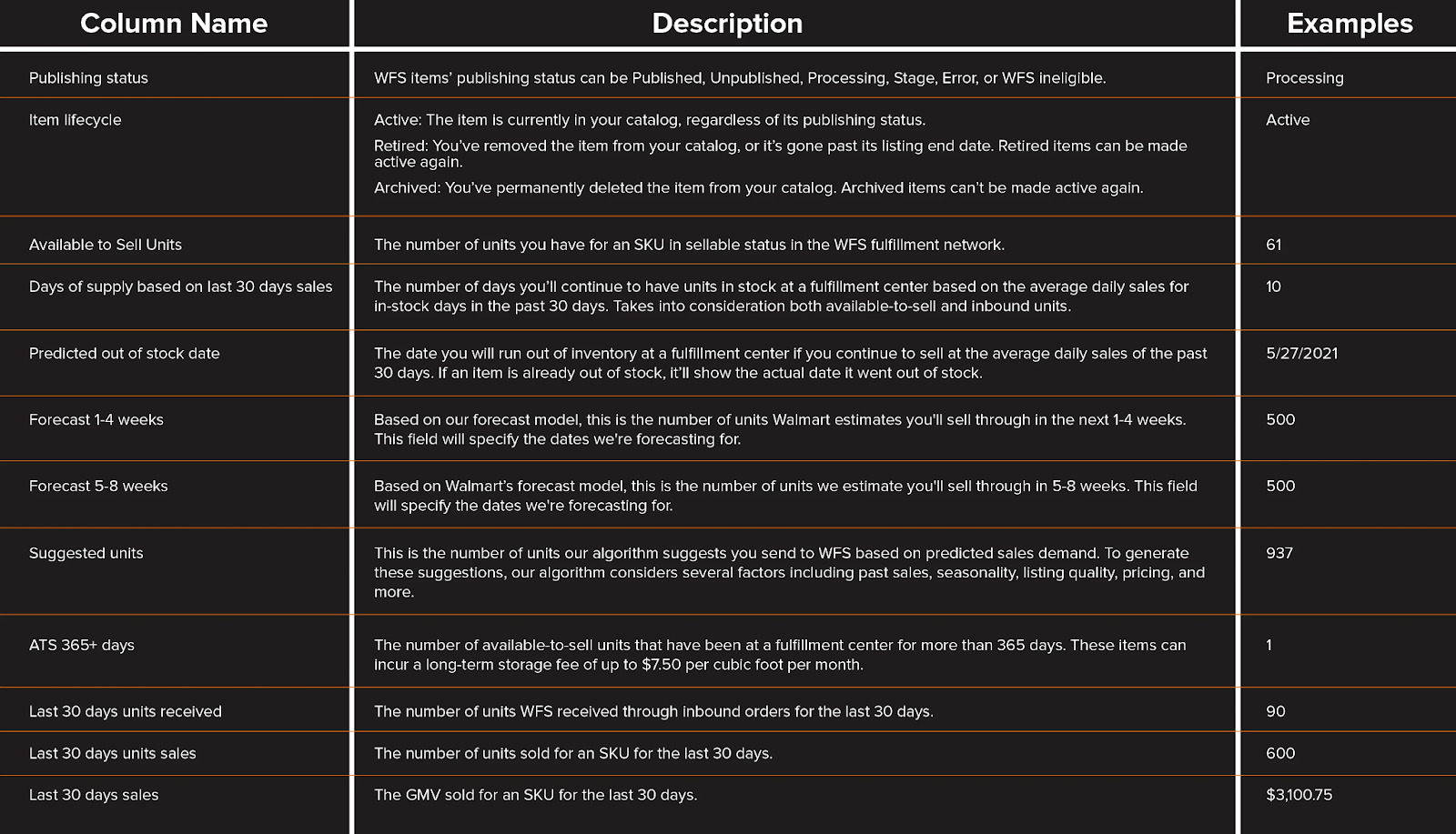

This report gives you a snapshot of your inventory performance. It allows you to track available-to-sell units, the storage time of the units, days of supply, and sales. Walmart suggests replenishment quantity based on the forecasted demand for the next 8 weeks while considering the available and inbound inventory.

This report can help you manage your Walmart inventory effectively and make informed decisions regarding replenishment.

The following are the most important elements of the Walmart Inventory Health Report:

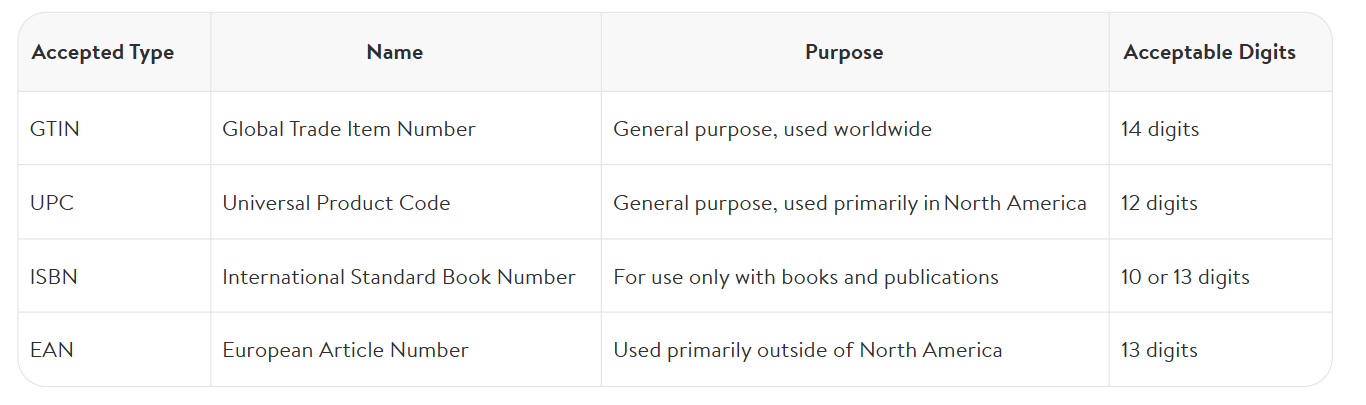

Walmart Product ID for Inventory Tracking

You need to have a product ID for every item in your Walmart inventory. This allows Walmart to track the items that are sold on the platform. Walmart accepts four types of IDs–you have to convert your ID into an accepted format if your items have a different type of ID. Below are the accepted ID types.

How to Request WFS Inventory Removal

You can remove items from the inventory by requesting Walmart to return the items to you. Walmart arranges the transportation and shipment while charging a per-unit fee for every item returned.

You’ll receive the items within 30 days of the request. However, the items may not be in their original cases/boxes and returned in unbranded or Walmart-branded boxes.

Here’s how you can request Walmart to remove your inventory:

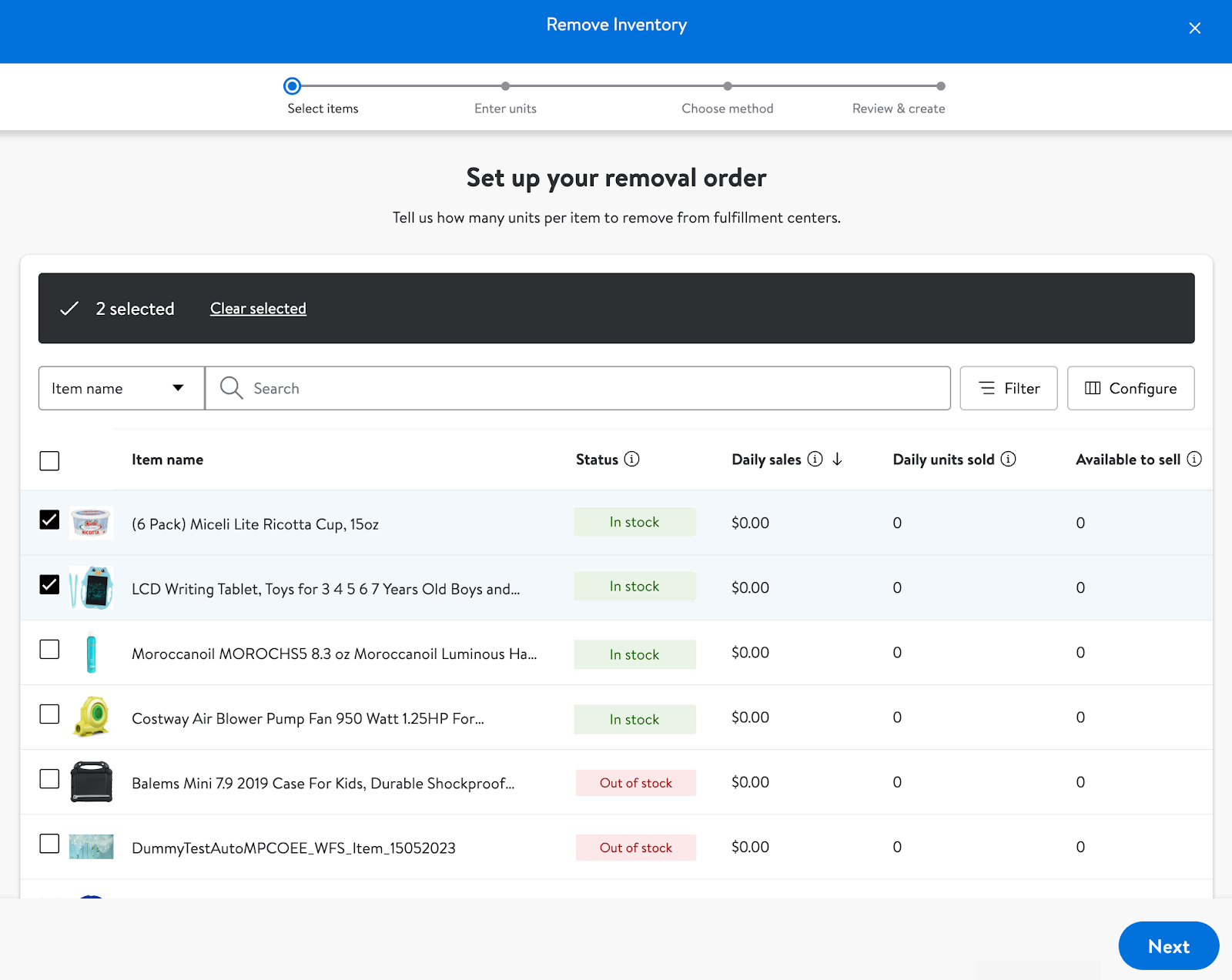

1. After logging into Seller Center, navigate to Removal Orders under WFS.

2. Click Remove Inventory.

3. After selecting the items that are needed to be removed, click Next.

4. Enter the number of units you want to remove and click Next.

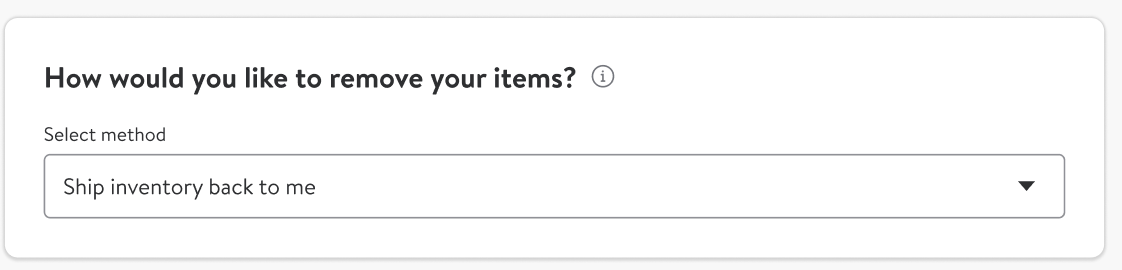

5. Select a removal option from the dropdown.

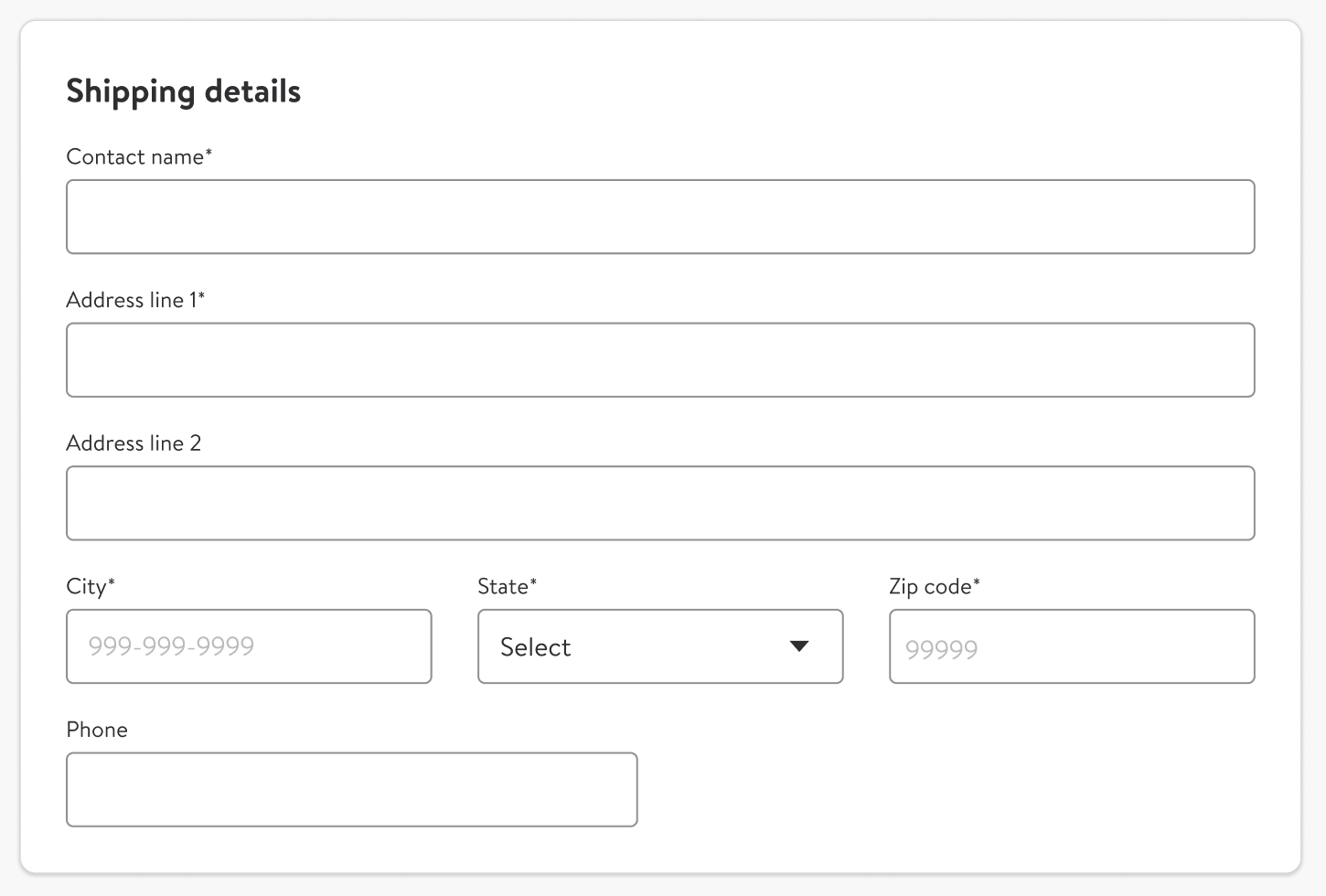

6. If you need inventory shipped back to you, provide the shipping address and ensure that the ZIP code is entered using only five digits.

7. You can edit the removal request to add more items before confirmation.

Best Practices for Effective Walmart Inventory Management

1. Understand Walmart’s Requirements

It’s important to be aware of WFS guidelines for effective inventory management. This includes inventory storage policies, storage charges, return policies, shipping policies, and specific rules for product categories.

You should also provide the correct product information, including authentic product IDs, titles, and descriptions. Correct information not only helps you avoid mismanagement but also minimizes returns by improving the customer experience.

Also Read: How to Avoid Walmart Account Suspension?

2. Use the Walmart Fulfillment Service

Set up an account on the Walmart Seller Center, the platform where you manage your inventory, product listings, and orders. The Seller Center provides tools and resources to help you efficiently manage your business on the Walmart Marketplace.

3. Manage Reordering and Replenishment Proactively

Effective reordering and replenishment strategies help maintain optimal inventory levels, preventing both stock shortages and overstocking. Sellers should use data-driven insights to identify ideal reorder points for each product.

A reorder point (ROP) is the inventory level at which a new order should be placed to ensure stock replenishment before depletion. It factors in lead times (the duration required for restocking) and average daily sales. Regularly adjust reorder points based on shifts in sales velocity and supplier lead times.

ROP Formula:

ROP = (Average daily sales × Lead time) + Safety stock

You need to adjust reorder points regularly based on shifts in sales velocity and supplier lead times.

4. Plan for Seasonal Demand

Managing inventory during seasonal spikes like Black Friday or the holiday season requires careful preparation. Without proper planning, sudden demand surges can lead to stock shortages and missed sales opportunities.

Looking at past sales data helps predict when demand will rise. By analyzing previous peak seasons, sellers can adjust stock levels to ensure they have enough inventory while avoiding excess stock that could lead to storage costs or markdowns. Planning ahead ensures a smoother sales period and maximizes revenue potential.

5. Make Data-Driven Decisions

Predicting demand accurately is key to good inventory management. By looking at past sales, seasonal trends, and using data tools, sellers can avoid running out of stock or overstocking.

Walmart’s analytics tools offer insights into sales, customer habits, and inventory turnover. Using this data, sellers can make better inventory decisions, keeping stock levels balanced and reducing extra costs.

6. Manage Returns and Reverse Logistics

Handling returns efficiently is a crucial part of Walmart inventory management. First and foremost, you should always provide the correct product information in your listings to improve customer satisfaction and reduce returns. However, if a customer returns an item, you need to inspect it and restock it to avoid loss. It’s recommended to use WFS return services to manage reverse logistics and restocking.

7. Build and Maintain Relationships with Suppliers

Building strong supplier relationships is key to keeping inventory flowing smoothly. Reliable suppliers can provide faster restocking times, bulk discounts, and better payment terms, helping businesses stay competitive.

Working with long-term suppliers who offer flexibility—such as shorter lead times or rush order fulfillment—ensures you can quickly respond to demand changes. It’s also smart to have multiple suppliers as a backup in case one fails to deliver, reducing the risk of stock shortages.

8. Use Inventory Management Software for Automation

Walmart inventory management software like Ordoro and eSellerHub helps sellers automate stock tracking, demand forecasting, and reorders. These tools integrate with Walmart Fulfillment Services (WFS) and other sales channels, giving a complete view of your business.

Automation features reduce manual work by tracking stock levels and triggering reorders when needed. Also, multi-channel integration lets sellers manage stock across platforms like Amazon, eBay, and Shopify from one system.

While these tools improve efficiency, they can be costly, which may be challenging for smaller sellers.

Final Thoughts

Inventory management is a crucial element of success for Walmart sellers. Whether you’re using WFS or fulfilling orders independently, maintaining optimal stock levels, preventing stockouts, and reducing storage fees can help you grow your business.

By implementing these strategies, Walmart sellers can optimize their inventory, reduce costs, and maintain a competitive edge in a rapidly evolving marketplace.

Got More Questions?

Monitor the Inventory Health Report and restock based on forecasts. Prevent stockouts with reorder points and clear overstock with promotions, bundling, or Walmart deals.

Use Walmart Seller Center and inventory management software for automation, tracking, and smart reordering. Organize SKUs by demand and seasonality.

WFS simplifies storage and shipping but requires proactive restocking. If self-fulfilling, manage logistics carefully for smooth order processing.

Monitor stock, use data-driven forecasting, build supplier relationships, plan for seasonal demand, and optimize product listings.

Use demand forecasting, optimize pricing, run promotions, reduce storage fees, and enhance product listings to boost sales.